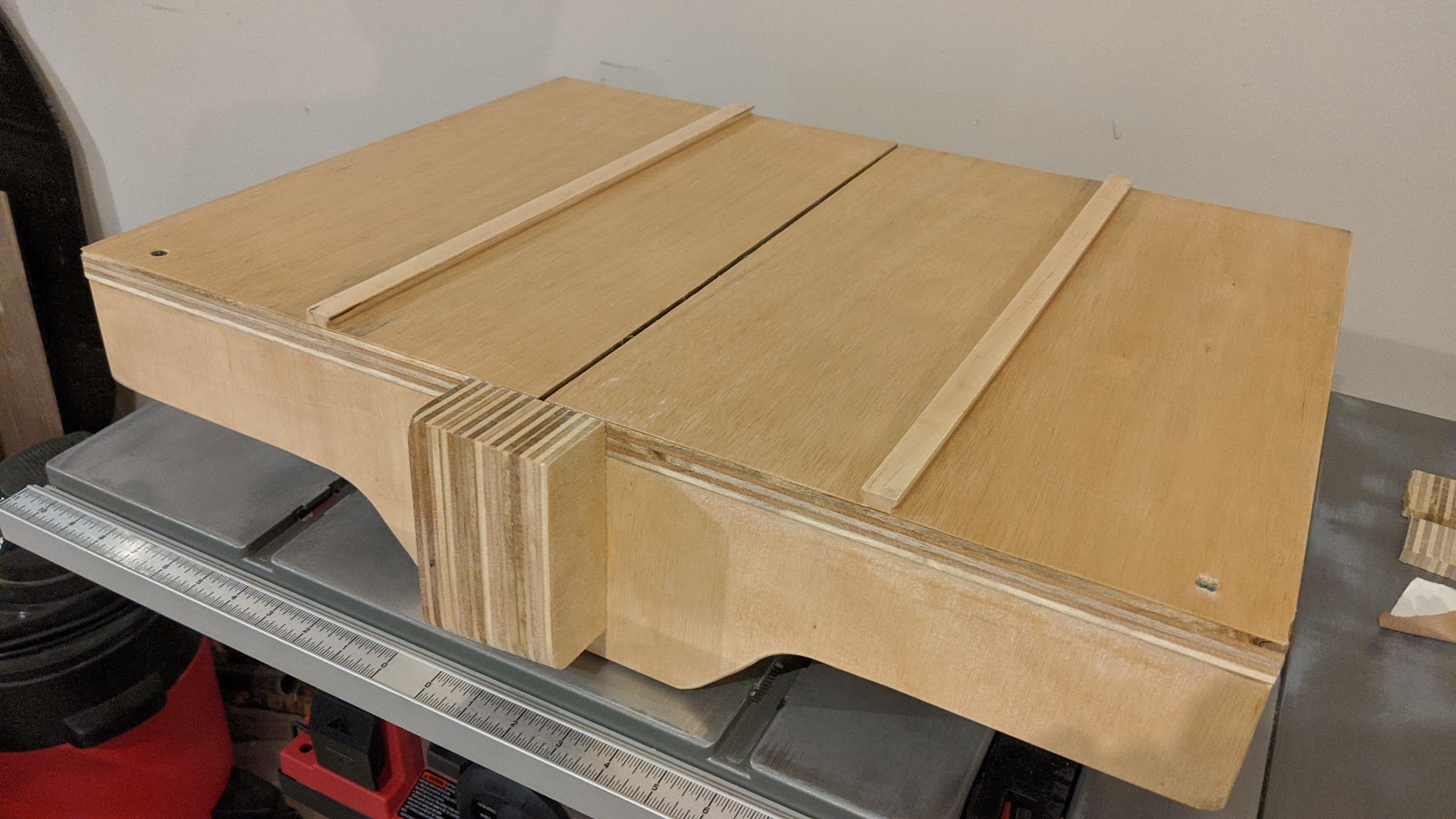

When I made my side table, this little bugger was ridiculously helpful.

I won’t go into a ton of detail on the build, because there are plenty of great examples on YouTube. Here’s one that I used.

Of note, my Skil 3410-02 table saw has tabbed miter slots. That complicated things when it came to the runners for my crosscut sled. I used this video for pointers on how to make the maple runners T-shaped to fit into the slots.

Once I got everything assembled and finished the sled with lacquer from a spraycan, the sled didn’t glide worth a crap on my table saw. This is because, for whatever reason, Skil made their tabletop with a grippy, sandpapery, surface. To fix this, I got out my palm sander, and sanded the top flat (or at least as flat as I could).

That helped some, but it still wasn’t great. So, I applied paste wax to both the underside of the sled, and to the table saw’s tabletop. Then, after letting it dry for a few minutes, I wiped it off (wax on, wax off… kind of like waxing a car).

Once that was done, the sled slid slick as snot.